The Food and Drug Administration (FDA or the Agency), the US regulating authority in the sphere of healthcare products, has published a guidance document dedicated to technical considerations for additive manufactured medical devices.

Table of Contents

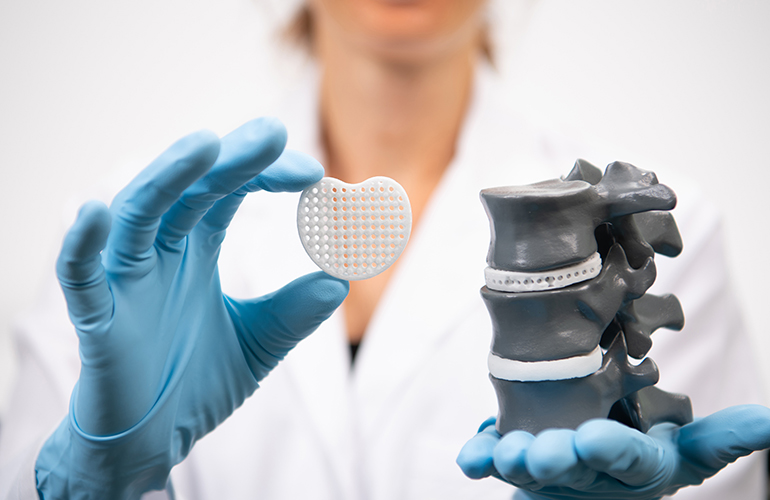

The document provides an overview of the applicable regulatory requirements for medical devices manufactured with the use of 3D-printing (additive manufacturing or AM) technologies and also highlights the most important aspects to be considered to ensure these products meet the respective safety and performance criteria. Due to its legal nature, the present FDA guidance is not intended to introduce new rules and requirements the parties involved should follow, but rather to provide additional clarifications and recommendations. Moreover, the authority also mentions that an alternative approach could be applied, provided such an approach complies with existing legislation and has been agreed with the authority in advance.

Overview

The regulatory requirements for 3D-printed medical devices are subject to, as well as the applicable level of regulatory scrutiny, depending on numerous factors, such as its functions and features, or the way it is intended to be used by its manufacturer. According to the guidance, when determining the scope of information to be provided when applying for marketing authorization, or the particular testing to be performed when assessing compliance with the applicable safety and performance requirements, the following factors should be considered:

- Whether the product in question is an implantable medical device or an instrument,

- Whether it is a reusable medical device or a single-use one,

- Whether it is a patient-match product or is available in several standard sizes, etc.

The Agency further states that this guidance outlines technical aspects of an AM device that should be considered through the phases of design development, production process, process validation, semi-finished and final finished device testing. At the same time, the authority additionally emphasizes that the considerations highlighted in the document are non-exhaustive, so the scope of assessment should be determined for each specific device on a case-by-case basis to ensure that device-specific aspects are duly addressed by such an assessment or the regulatory controls applied. According to the document, it is the sole responsibility of a medical device manufacturer to determine, based on the materials and technologies used, the requirements and assessment methods to be applied. For instance, some of the considerations are applicable only concerning specific manufacturing technologies and do not apply to others.

Thus, not all the aspects covered by the present FDA guidance should be considered when applying for approval for marketing and use. Under the general rule, a medical device manufactured with the use of additive manufacturing technologies should be subject to the same general safety and performance requirements as a similar medical device manufactured in a usual way. However, in certain cases, the use of additive manufacturing technology results in additional requirements to be applied due to the specific nature of these manufacturing methods and risks associated thereto. The authority also encourages medical device manufacturers to contact the respective bodies in case they have any doubts about the scope of information provided to get additional clarifications and recommendations to be followed in the specific case. In this regard, the document refers to the FDA guidance “Requests for Feedback on Medical Device Submissions: The Pre-Submission Program and Meetings with FDA Staff” which provides additional clarifications regarding interactions with the regulating authority before the submission of a premarket application.

To assist medical device manufacturers in following the principles described in the guidance, the FDA also provides a flowchart demonstrating the process related to additively manufactured medical devices. According to the flowchart, the process includes the following steps:

- Initial design and development (as a result of this stage, the device design should be converted to a digital file);

- Software workflow (includes preparing of a device digital file for printing, i.e., optimization of parameters);

- The manufacturing process (here is where the material control should take place);

- Post-processing (including cleaning, annealing, post-printing machining, sterilization, packaging, and labeling);

- Final testing considerations.

The authority also states that the quality system implemented by the manufacturer should be applied at all stages.

Definitions

Apart from the general information about the applicable regulatory requirements, the document also provides the definitions of the most important terms and concepts used in the context of additive manufacturing of medical devices. These terms include, inter alia, the following ones:

- AM Machine – a portion of the additive manufacturing pipeline including hardware, machine control software, required set-up software, and peripheral accessories necessary to complete a build cycle for producing parts;

- Build Cycle – single process cycle in which one or more components are built up in layers in the process chamber of the additive manufacturing system;

- Build Preparation Software – means the software used to convert the digital design to a format that can be used to build a device or component through an additive manufacturing process. As further explained by the FDA, the concept of a build preparation software could cover multiple software components.

- Design Manipulation Software – stands for the computer program that allows a medical device design to be modified for specific circumstances (e.g., patient-matching). As in the case of build preparation software, this concept could also include multiple software components.

- Lot or Batch – one or more components or finished devices that consist of a single type, model, class, size, composition, or software version that are manufactured under essentially the same conditions and that are intended to have uniform characteristics and quality within specified limits.

In addition to the definitions listed hereinabove, the FDA also provides the definition of “quality” which, for the guidance, stands for the specific features of the product ensuring that it meets that applicable safety and performance criteria, and also fits the intended purpose.

In summary, the present FDA guidance highlights the most important aspects associated with the use of additive manufacturing technologies for producing medical devices. The authority outlines the main factors to be considered when determining the scope of requirements for the product and its manufacturing process, and also provides the definitions of the main terms and concepts used.

Sources:

How Can RegDesk Help?

RegDesk is a next-generation web-based software for medical device and IVD companies. Our cutting-edge platform uses machine learning to provide regulatory intelligence, application preparation, submission, and approvals management globally. Our clients also have access to our network of over 4000 compliance experts worldwide to obtain verification on critical questions. Applications that normally take 6 months to prepare can now be prepared within 6 days using RegDesk Dash(TM). Global expansion has never been this simple.